- Research & Instruments

- How we study - Our instruments and methods

- Instruments and Methods

- Workshops

- Electronics Workshop

Electronics Workshop

What is done in the electronics workshop?

In the electronics workshop, the technicians develop electronics for research equipment that must function under very difficult environmental and operating conditions. These devices and appliances cannot be purchased. Many of the devices used by researchers at our Institute need to function when immersed in water – and that is a feature that most electrical devices lack to begin with. Designing equipment for use in the oceans is a great challenge. The devices must be able to withstand high pressure and a wide temperature range. They must also be extremely corrosion resistant.

There are three technicians in the electronics workshop. They develop and produce the devices together with the researchers and the technicians from the other workshops. The electronics workshop is only a part of the device development. It all depends on the successful interaction between scientists, the electronics workshop, the mechanics workshop, and the researchers out at sea. In some cases, the workshops also work together with scientists and technicians from other research institutes. Without teamwork, even the best idea cannot be implemented.

Many of the devices developed at our Institute are regularly used by other research institutions. For example, the “Profilur” and “Lance-A-Lot” profilers as well as various chamber landers. The “Tramper” benthic crawler is a new development that was created in cooperation with the Alfred Wegner Institute. Other scientists have filled an existing gap in the market. Spin-offs such as Presens, Pyroscience, and Plan Blue have emerged.

In addition to the development of research equipment, it is also a very important task of the electronics workshop to maintain and repair existing equipment at our institute.

How is research equipment developed?

If scientists at the Institute need a special device for their research, they can contact the electronics workshop. The electronics engineers first need to know what experiments the scientists want to do in situ (i.e. in the sea). Often, the researchers only come to the workshop with a relatively vague idea. Together with the engineers, they think about how the experiments can be carried out and what data needs to be collected. With these ideas, the engineers create initial designs that are tested for suitability in many experiments.

Then it’s on to the implementation. The parts that are available to buy (e.g. underwater batteries) are purchased. Everything else is built by the technicians. It is often a matter of measuring parameters such as oxygen, salt, temperature, and pH value. The engineers build the necessary electronics to collect and record the measurement data. The devices need a control system, which also requires sophisticated electronics. For a first prototype, all parts are integrated. The technicians and scientists then conduct tests in order see whether they work together as planned.

If you want a complete system that you can throw overboard and bring back without hesitation, you have to factor in at least a year of development time. Despite numerous tests before the trip, the device can nevertheless fail. It can then be repaired or revised. Because of the time-consuming planning of excursions, the retest of the revised device can take up to one or two years. Occasionally one of the electronics engineers goes on the ship with the device. However, this is the exception because of the high expense and the limited space on board. The scientists therefore need to be familiar with the devices and basic technical functions so that they can operate them on the ship and fix minor problems themselves.

It is therefore quite exciting whenever the new developments are used in the field for the first time. The first use of a newly developed device is also an adventure for the electrical engineers – even if they are not on board.

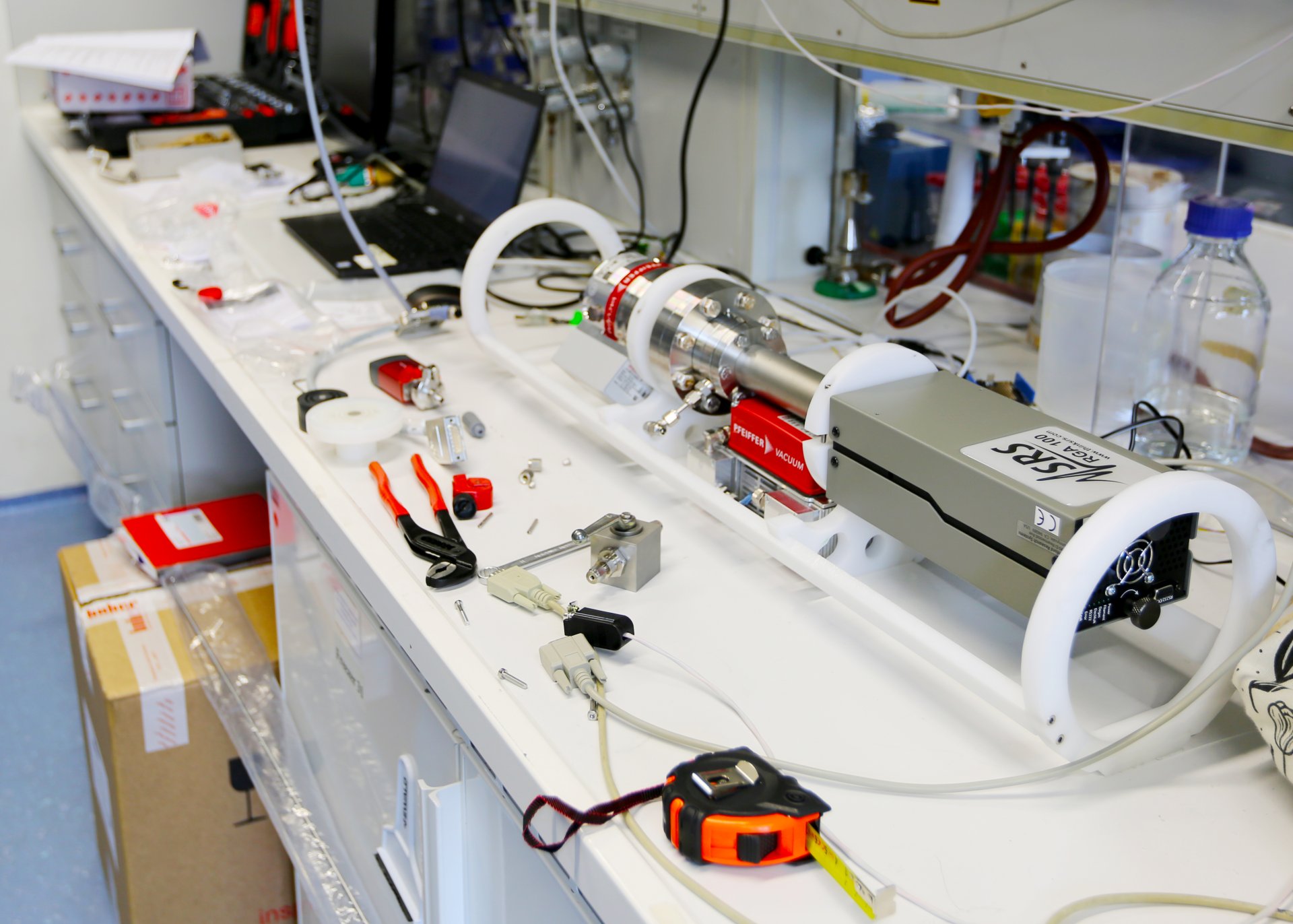

Example: in situ mass spectrometer

The technicians of the electronics workshop are currently working on a large project that the MPI is carrying out together with MARUM. The Quest remotely operated underwater vehicle (ROV) is to be equipped with a “sniffer nose”. This nose, a mass spectrometer, is to be enclosed in a waterproof and pressure-resistant housing and integrated into the infrastructure of the Quest. The aim is for the researchers to be able to find water leaks (vents) on the seafloor during dives with the ROV based on the gases they emit into the water.

For this purpose, the control and data collection of the mass spectrometer must be transported via the ROV to the ship. To this end, the engineers are developing and programming a microcontroller board that is specially tailored to the needs of the mass spectrometer. Together with our scientists, software is being developed to display the data from the mass spectrometer on board and to control the device. Special demands are placed on precision mechanics. The 0.2 mm-thin membrane through which the gases pass from the water into the “nose” of the mass spectrometer must be tensioned so that it can withstand a pressure of 400 bar. This is particularly important work. If the membrane tears, water will penetrates the sensitive measuring electronics, and the mission will fail.

That’s why everyone is working together towards one goal – the “sniffer nose” for the Quest.

Who uses the electronics workshop?

The electronics workshop is open to all employees at the Institute.

Please direct your queries to

MPI for Marine Microbiology

Celsiusstr. 1

D-28359 Bremen

Germany

|

Room: |

1302 |

|

Phone: |